College’s Baobab Plant Operational

Share

MUTARE- The US$125 000 baobab and juice manufacturing plant situated at

Mutare Teachers College is fully operational with positive projections on the

improvement of rural livelihoods in and around Manicaland.

The construction of an automated juice manufacturing plant in Mutare is in line

with Government’s drive to industrialise the economy, as this is among the

Second Republic’s milestone achievements.

What makes the project unique is that it is being implemented by students under

the Education 5.0 initiative.

Mutare Teachers College’s Food Science lecturer, Jabuliso Ncube says the US$

125 000 plant has the capacity to produce 2 000 litres of Baobab juice per hour.

“This plant was purchased for the college by the Ministry of High and Tertiary

Education, Innovation, Science and Technology Development as part of the

empowerment programme under the education 5.0 model. The ministry

purchased this plant from China. The plant is meant to produce bottled water,

and fruit juices in various varieties though first priority is to be given to the

baobab fruit juice,” he said.

The processing plant has a capacity of 2000 litres per hour and can also process

other fruits including indigenous fruits such as matamba, mazhanje as well as

exotic and locally available fruits including pineapples, oranges, mangoes and

guavas as well as mineral water.

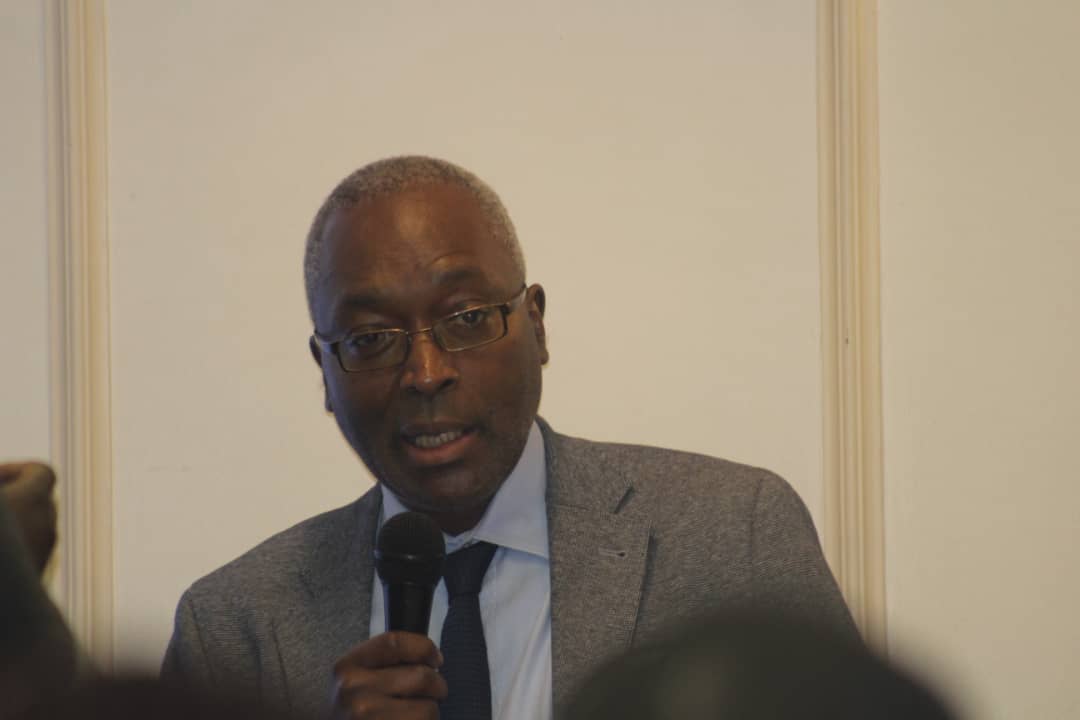

Speaking on tour of the processing plant, Minister of State for Presidential

Affairs and Monitoring, Implementation of Government Programmes, Joram

Gumbo said the processing plant was a game changer for rural communities for

the major impact of the project is set to benefit downtown communities.

“Initially the plant was meant to be a baobab processing plant but looking at the

geographic location of Manicaland, and the variety of fruits readily available in

the region there is need to be able to make juices from a wide range of

indigenous fruits. This not only adds economic value to the locals but is of

nutritional benefit to the consumers.

“It is a versatile kind of equipment and we are very happy that we are going to

empower a large section of communities where we draw the raw materials

from,” said Minister Gumbo.

The 2000 litre per hour versatile processing plant has a cooling section, an

automated filling and capping section, a bottle blowing section, purifier,

conveyor belt, mixing tanks and laminating sections at the exit points of the

production chain.