‘The first cut is the deepest’ – The story of Morris Patrick Dube Business Chat

Share

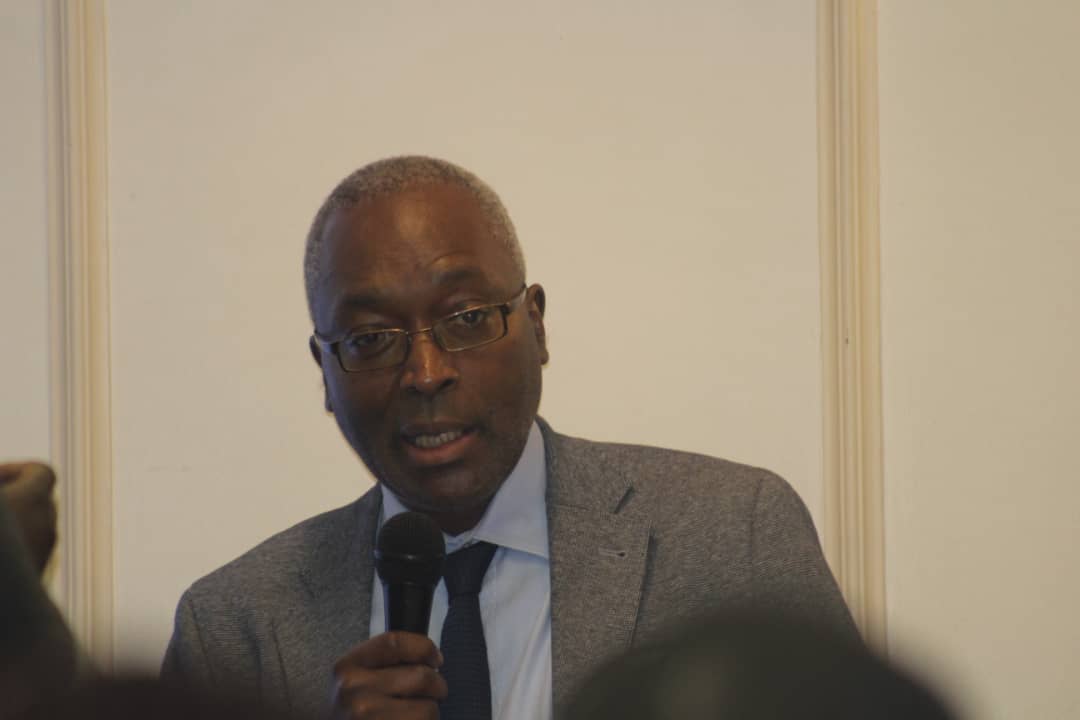

THEY say the first cut is the deepest. And this rings true for 55-year-old Morris Patrick Dube. In

Shona they say: Chakabaya chikatyokera (meaning, it went in and got stuck inside). After completing

his “O” levels at Gifford High in Bulawayo, Dube landed his first job at Plate Glass (PG). He would stay

there for the next five years working as a carpenter.

At PG he received a lot of in-service training but never got a certificate for the competence he

acquired there. During those days, the most honourable thing to do was to pursue a course and get

a certificate. So, in obedience to that mentality, Dube went to train as primary school teacher at the

Joshua Mqabuko ZINTEC College.

To this day, Dube proudly talks of being amongst the pioneers of the ZINTEC. After teacher training.

Dube went on to teach at a number of schools in Gwanda South District. These included Silonga, Payi

and Matanhamombe. Interestingly, Dube would make furniture whenever he had time to spare.

Apparently, the stint at PG had made indelible impressions on his mind. The passion had grown deep

enough not to be shirked off easily.

In 2005 when the pangs of economic hardship became more accentuated, Dube felt it was time to

make a life-changing decision. He had come to the crossroads of his career in life. The course of his

life was set to change forever.

Without much notice, he ditched the black-board chalk for the smell of fresh pinewood. He left

Silonga and came to Gwanda, where he set up a carpentry shop at PG yard in the industrial site. He

would later move to his present premises near the municipal fire station.

He is renting space from the National Railways of Zimbabwe at number 61 GA. The relocation was

prompted by the need to be nearer to the customers.

Dube’s company, Wackhead Furnishers, has a staff complement of three carpenters, including

himself and a highly competent and certificated welder, Joel Pasipamire. In a month, they churn out

at least 10 bed bases and five wardrobes. Incidentally it was the beautiful bed bases that caught my

eye.

Dube’s trade tools, which include saws and planes, are all electrical. Quality is at the centre of

everything they do at Wackhead. For instance, they make sure they never use chipboard or wet

wood. They use pinewood which is both durable and affordable. Besides assuring quality, the

electrically-driven technology means a faster rate of production.

The prices of the bed bases range between $70 and $100 and the wardrobes vary from $100 to

$180.They understand that money is hard to come by during these times. They offer the lay-by

facilities to their valued customers and moreover their prices are negotiable.

Wackhead also manufactures an assortment of other furniture items which include school furniture,

household furniture and the odd shop counter. Besides manufacturing new furniture, they also

repair furniture. The items which often come for repairs include the bed bases locals smuggle from

across the Limpopo.

Dube is quite happy with the way business is going. However, like any other business, they are not

without their own challenges. Big customers like schools would part with their cash only after they

have collected their goods. This puts a strain on their cash flows.

Dube looks forward to the day when the Government stop focusing on the youths only and extends

a financial hand to all the other SME’s as well. Moreover, it is the mature and experienced

businesses which are in a better stead to put the funds to good use. Unlike most small businesses,

Dube’s vision is to grow his business into a large concern employing many people and serving a

bigger customer base.

The first cut is most likely your dream. Chase it and it will take you to dizzy heights. That is the advice

Dube gives to aspiring entrepreneurs.